High-pressure self-tight flange  > PRODUCT INTRODUCTION

> PRODUCT INTRODUCTION

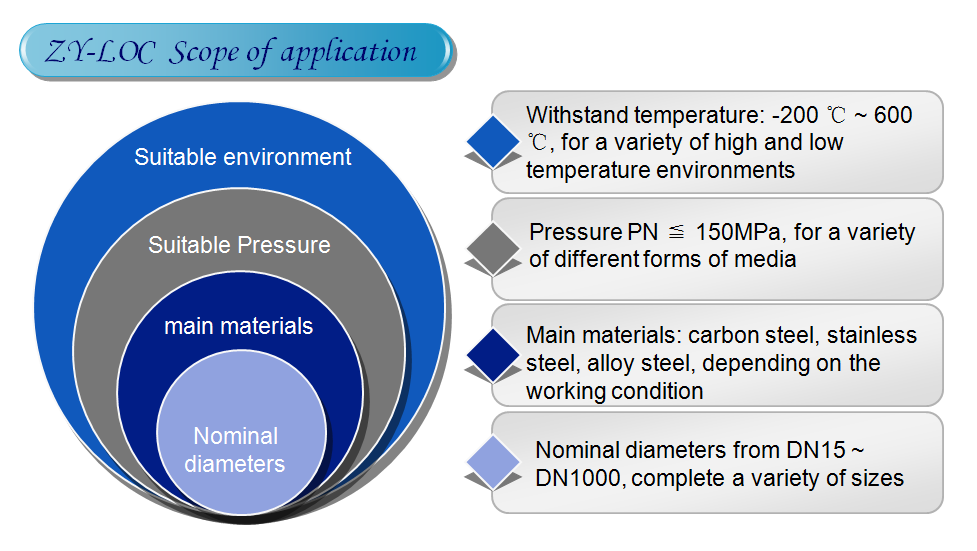

High-pressure self-tight flange “ZY-LOC”

High-pressure self-tight flange has made radical revolution at structure and mechanics performance, and solved the traditional four big malpractices of run, emit, trickle and leakage. The higher the pressure, the better the self-tight sealing property, hence it had the superiorities of environmental protection, energy conservation and security. Moreover its small size, light weight, high strength, good toughness, disassembly and installing conveniently, and especially the unique metal-metal sealing way make the high-pressure self-tight flange surpass other flange products by far in the safety performance, therefore it has the epoch-making progress. !

High-pressure self-tight flange technically tested by our company for many times, is in accordance with the technical design index, during the examination of Oil Industry and the appraisal of the Safety Engineering Research Institute of the China Petroleum &Chemical Corporation, it received a high praise, and opened a new way in this domain of our national industry.

High-pressure self-tight flange can be widely applied to the areas of oil gas mining, petroleum fining, chemical industry, aerospace, nuclear industry, ships industry, synthetic fuel processing and so on. Now it has been successfully selected to apply to the largest state-level GTL installment of Inner Mongolia by China Petroleum &Chemical Corporation SEI.

PRODUCT FOR MATION

A High-pressure Self-tight Flange ZY-LOC is Composed of Four Parts.

|

Metallic Sealing Ring: The sealing ring is the core of high-pressure self-tight flange,looking like a T-shape cross-section. After the flange is installed, T-shape rib is retained by the end-faces of two hubs and form a entirety with the main tube (connect through the clamp), and enhance the joining strength greatly; the two arms of T-shape form sealing lip, and form a sealing region with the inner taper surface of hub, this region is like a spring, under outside force(pressure), it can stretch freely in the range of yield stress and form sealing. |

|

Two Hubs: The two hubs is fastened by the clamp, and pressed on the rib of sealing ring. When the clamp pulls the hubs together, the lip of sealing ring (two arms of T-shape) deviates from the inner sealing surface of hub. This deviation makes the load of inner sealing surface of hub back to the lip of sealing ring elastically, and a self-strengthening spring sealing is formed. |

|

Clamp Set: The connection between two clamps can be adjusted within 360, the relief canal in the middle of clamps can make the stress adequate distributing, and can position freely in 360 orientation when installing. That will be very convenient. |

|

Four Spherical Bolts: The flange is bound to be a whole through four tangential high-pressure sphere bolts. |

Analyze ZY-LOC

1、Seal ring’s rib and HUB become a strong rigidity and increase its strength.

2、Seal ring’s lip and HUB’s conical surface fit closely with each other. When the pressure change is within the σs, the lip and Hub can become an elastic seal part.

3、The gap “h” between HUB and rib need to be calculated strictly. When the bolting F make the h=0, there is F1 and F2 on the lip. And it forms the beginning seal pressure. When the pressure raises gradually, F1 and F2 rises gradually. It seals.

4、ZY-LOC seal ring separates strength and sealing, so there is no traditional flange’s arm of force H, it is elastic seal. This is the basic difference in force.

5、Rib, HUB, clamp and bolting become a strong rigidity which protect the lip seal well without the impact from outside(like pressure change and added load).

Analyze Seal ring T arm force

F:The first mechanical Force is caused by bolting.

F1:The second mechanical Force Caused by pipeline pressure

Spring principle: seal ring’s lip elastic deformation is controlled within a limit σs.